- Created: April 2016

- Materials: Aluminum, Stainless Steel

During my last quarter at Stanford I enrolled in ME318, where we learned how to operate a CNC (computer numerical control) machine. The second assignment, intended for students to get more comfortable with the machines and the software, was to create a bottle opener.

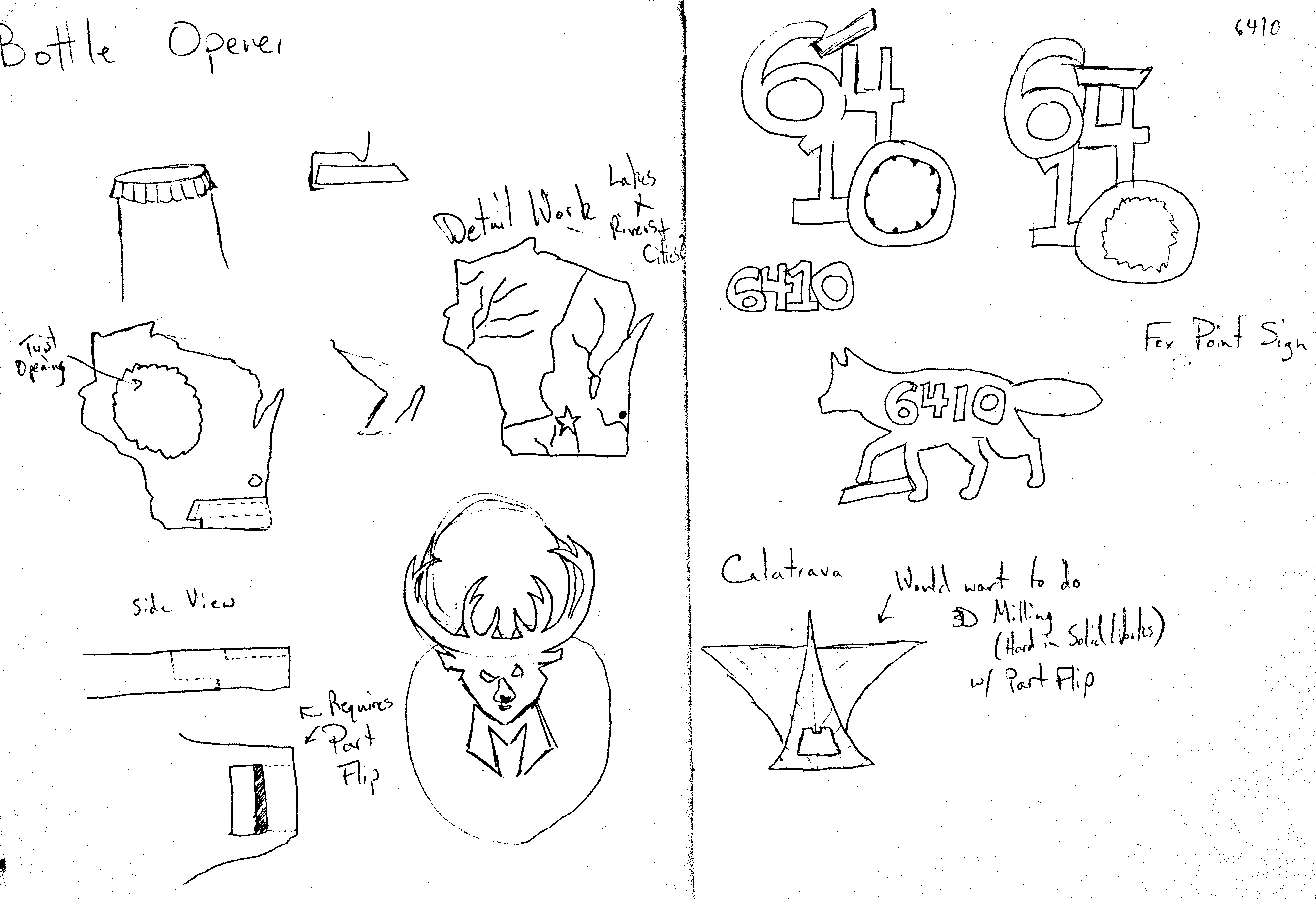

Coming from a city and state known for its beer, Milwaukee, Wisconsin, I wanted to come up with a design related to home. Possible ideas included the shape of Wisconsin, using the Milwaukee Bucks logo, or an outline of the Milwaukee Art Museum. I also considered designs that were less recognizable, but more personal and still related to my home, like the house number of the house I grew up in (6410).

Technically I lived in the village of Fox Point, not in the city of Milwaukee. When you search "Fox Point" on Google, one of the first results shows a "Village of Fox Point" sign. The driveway in the backround of that sign is the driveway to the house I grew up in! And on the sign is the outline of a fox, which I decided to use as basis of my design. It was also the simplest of the designs I drew up, requiring minimal 3D milling.

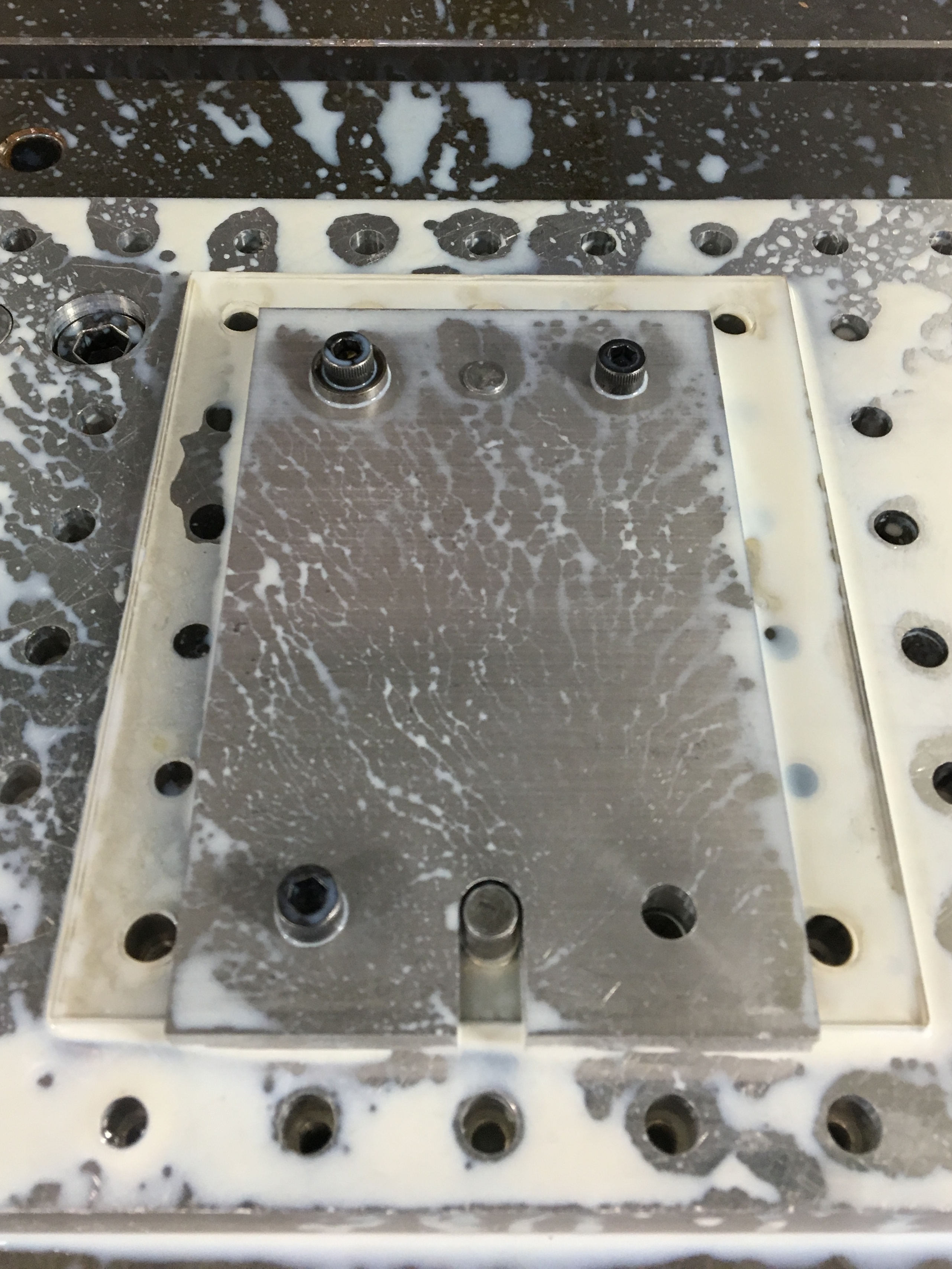

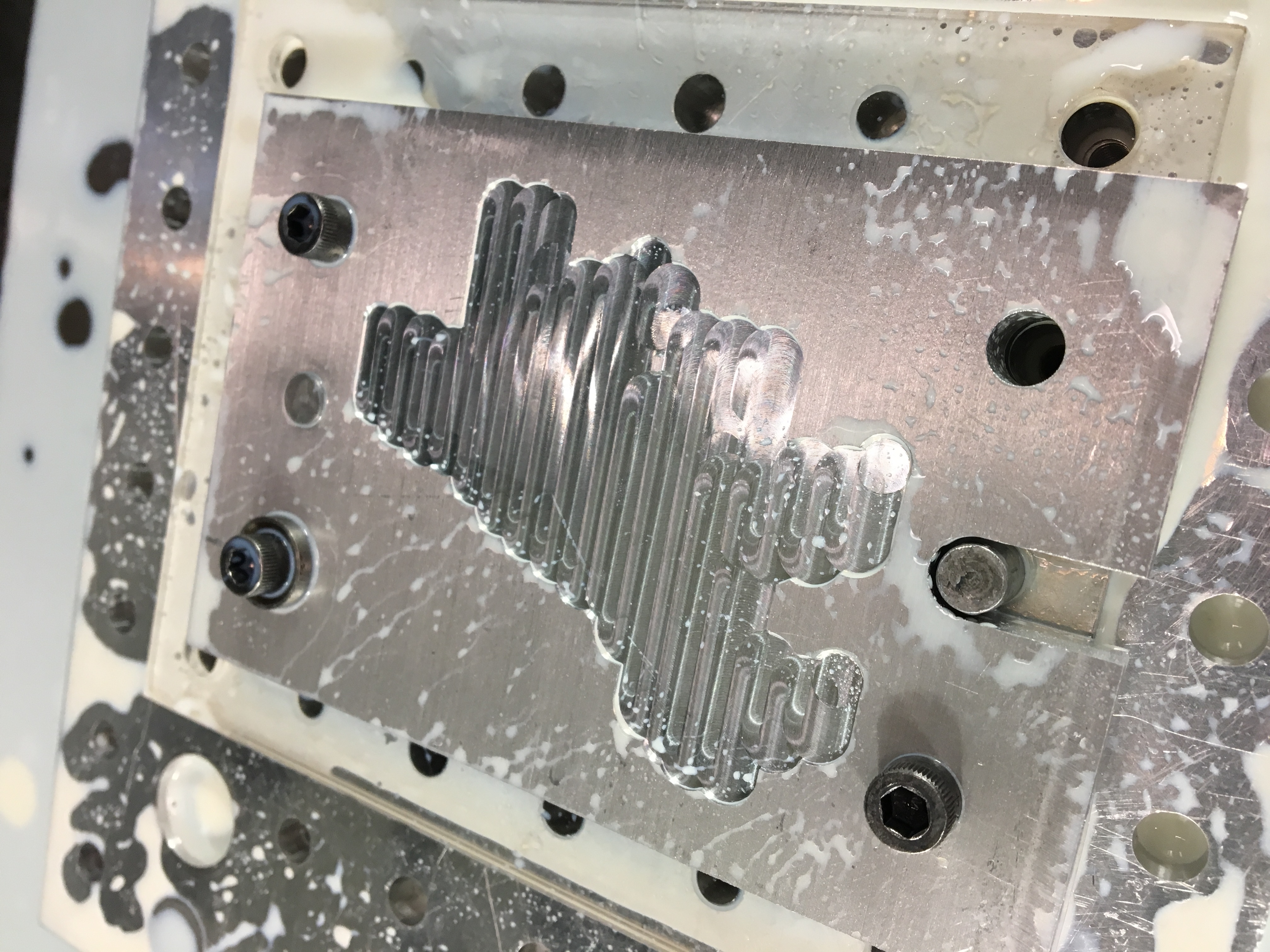

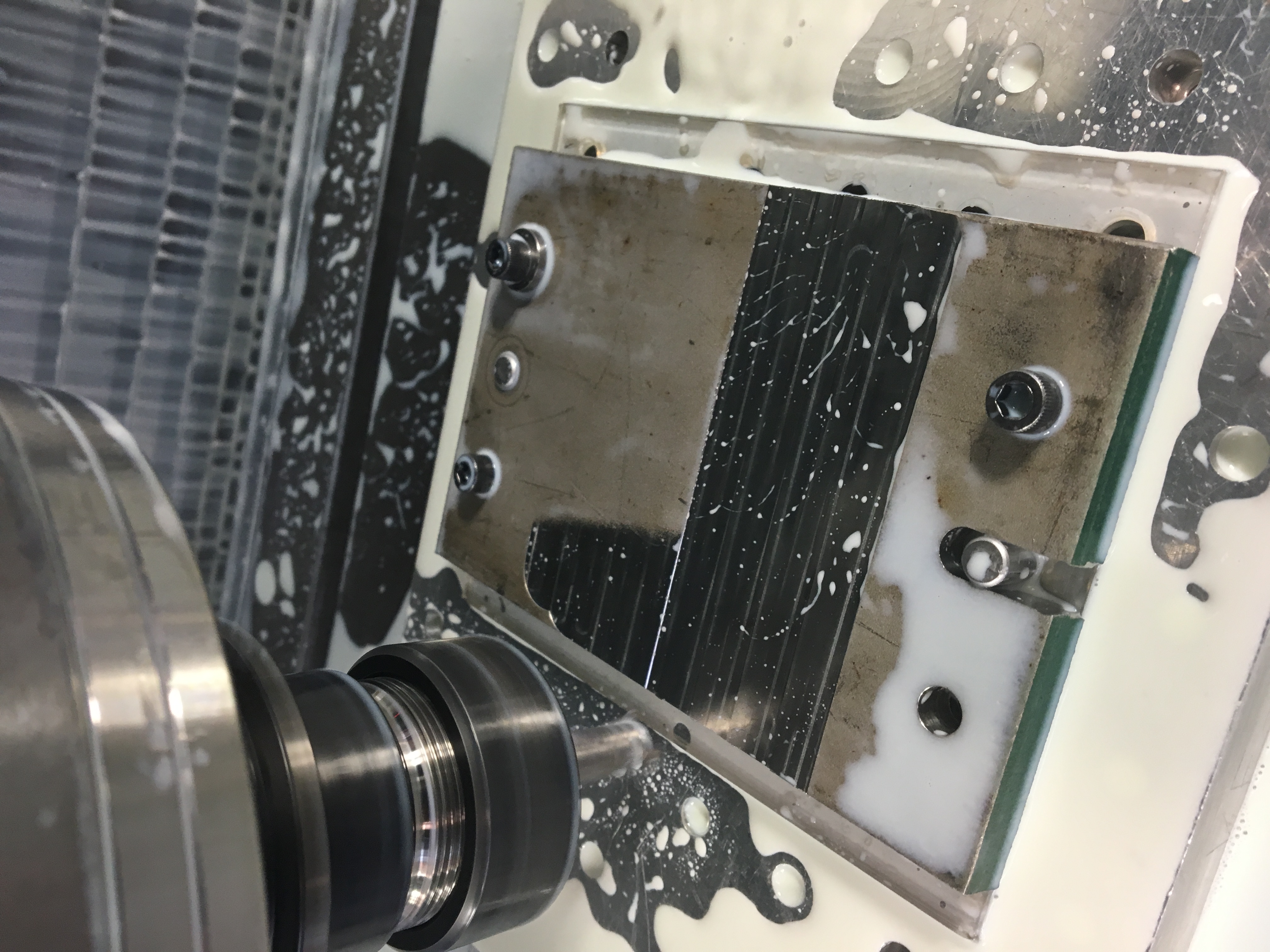

I machined the bottle opener from an aluminum plate. The plate in the first picture is already covered in coolant after an initial sanity check airpass.

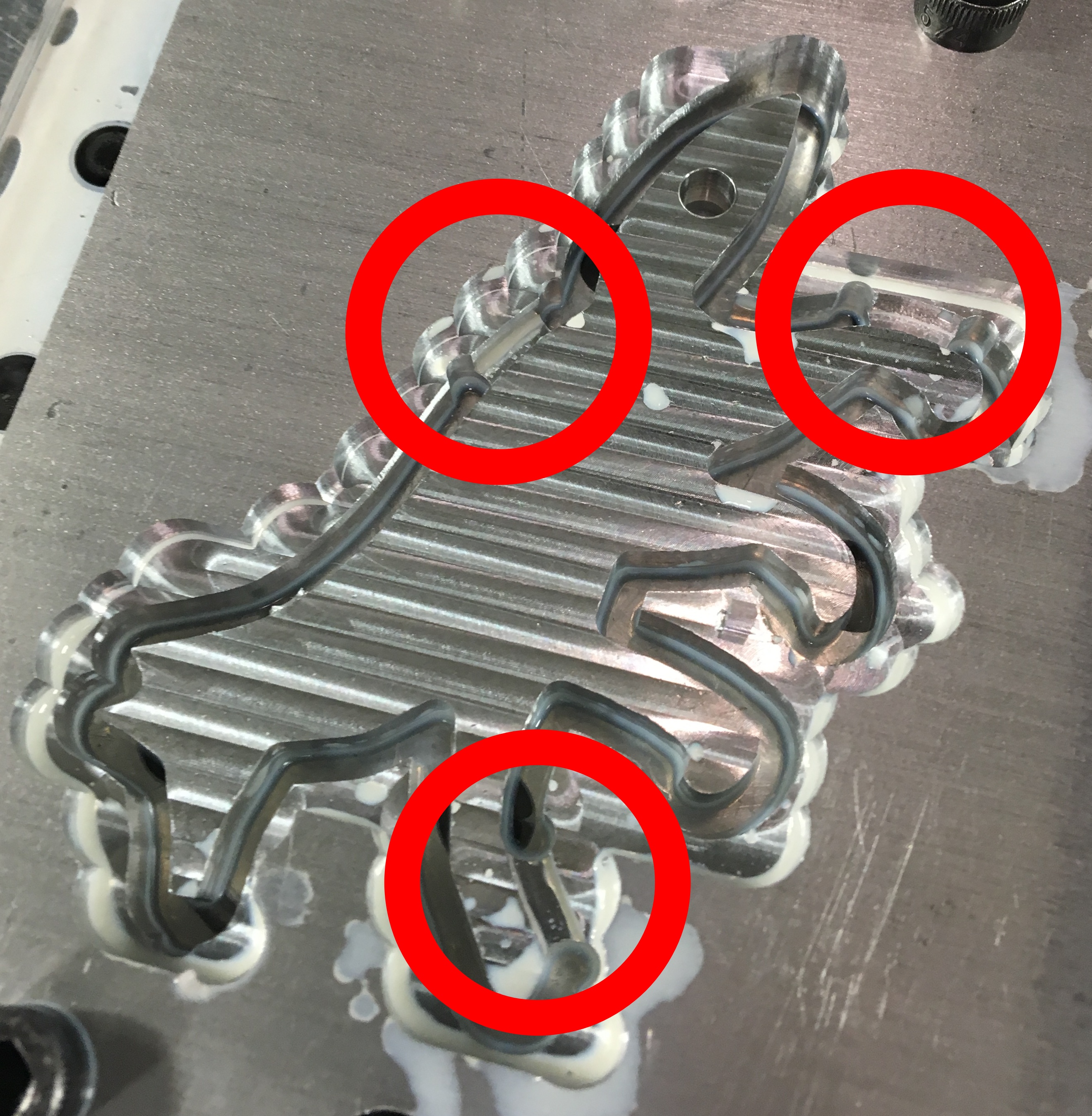

A piece cannot be complete cut away from its stock material unless additional fixturing is added to keep it in place part-way through the machining. Alternatively, small "tabs" of material can be left uncut and the final piece can be cut away from the stock by another tool. In my case I left three tabs: one on the back towards the tail, one underneath the first foreleg, and one on the back of the last leg.

I made a second version out of stainless steel for my mom for Mother's Day. While I sanded away the machined finish on my aluminum one, I wanted hers to have the nice machined finish, which required facing both sides of the stock plate. Normally the entire face should be surfaced before drilling the fixturing holes to ensure that the top plane is perfectly parallel to the bottom plane, but that exactness wasn't required for this piece so I skipped that step. For the stainless steel version I also moved the location of the tabs slightly so that they were on flatter portions where would be easier to cut with a band saw and easier to sand.

My mom enjoyed her Mother's day present, while my first aluminum version always follows me around on my keychain, forever a reminder of home.